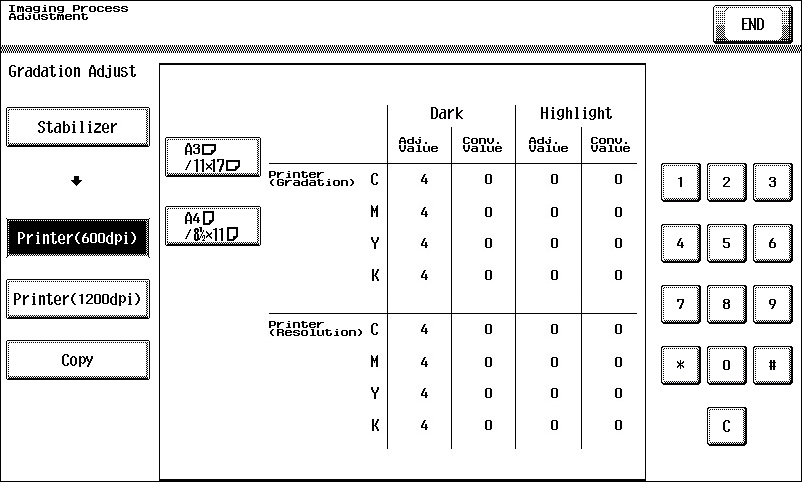

2.1. Gradation Adjust

- To make an automatic adjustment of gradation based on the test pattern produced and the readings taken by the scanner.

- Gradation or density reproduction performance becomes poor.

- The drum unit, developing unit, or transfer belt unit has been replaced.

- The Adj. Values of “Dark” and “Highlight” shown on the gradation adjust screen represent how much corrections are made to produce an ideal image output. Conv. Value shows the difference from the ideal image density.

- The closer the Conv. Value to 0, the more ideal the image.

Mode key | Description |

|---|---|

Stabilizer | The image stabilization is performed. The controller reflects the image stabilization result in the gradation adjustment table to update the table. After the image stabilization is performed, [Printer] / [Copy] key will become selectable. |

Printer (600dpi) | Detect the gradation reproducibility of the gradation reproduction method (gradation screen, resolution screen) for 600dpi print mode, and correct the gradation adjustment table. |

Printer (1200dpi) | Detect the gradation reproducibility of the gradation reproduction method (gradation screen, resolution screen) for 1200dpi print mode, and correct the gradation adjustment table. |

Copy | Detect the gradation reproducibility of the following gradation reproduction methods, and correct the gradation adjustment table.

|

<Procedure>

NOTE

- When executing the gradation adjustment, make sure to use the white paper for color copy.

- Touch [Stabilizer] and the Start key to perform image stabilization.

- NOTE

- Before executing Gradation adjust, be sure to perform Stabilizer.

- Select Print or Copy and select the paper size on which test pattern is printed.

- NOTE

- When [Printer (1200 dpi) is specified, [A3S/11x17S] not displayed.

- Press the Start key to let the machine produce a test pattern.

- NOTE

- When the image stabilization performed in step 1 is NG, the Start key stops functioning.

- When one of the alert codes, P-5, P-6, P-7, P-8, P-9, and P-28 is on the screen and [Printer] is selected, the Start key stops functioning.

- When "Printer (1200 dpi)" is specified, two sheets of A4 or 8-1/2x11 paper will be output.

- Place the test pattern produced on the original glass.

- NOTE

- Depending on the size of the test pattern, it is set in a different position. Set the test pattern according to the instructions displayed on the control panel.

- Place ten blank sheets of paper on the test pattern and lower the original cover.

- Press the Start key. (The machine will then start scanning the test pattern.)

- Touch [OK] and repeat steps from 4 through 8 twice. (a total of three times)

- Touch [Gradation Adjust] to display the Adj. Values and Conv. Values of each color (C, M, Y and K) for Dark and Highlight.

- Use the following procedures to check the Conv. Value.

- Dark: 0 ± 100 and Highlight: 0 ± 60: It completes the adjustment procedure.

- If neither Dark nor Highlight falls outside the ranges specified above: Perform steps from 4 to 8.

- If the convergence falls within the specified range after the second Gradation Adjustment, further adjustment may not be necessary.

NOTE

- If a fault is detected, “0” is displayed for all values. In that case, after turning off the main power switch, turn it on again more than 10 seconds after and then make the gradation adjustment again.

- If either dark or highlight still remains outside the specified ranges perform [Service Mode] -> [Imaging Process Adjustment] -> [Max Image Density Adj].

- If a total of four sequences of gradation adjust do not bring the values into the specified range, check the image.

- If the image is faulty, perform the troubleshooting procedures for image problems.