7.3. Intelligent media sensor

- With the intelligent media sensor (IM-102) being installed, it is possible to detect the paper kind of the feeding paper.

- The intelligent media sensor is equipped with the sensor for detecting the envelope and the sensor for detecting the basis weight.

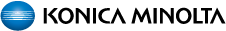

Configuration

1 | Registration roller | 2 | Envelope detection board/RX (ENVDB/RX) |

3 | Paper basis weight detection board/TX (PBWDB/TX) | 4 | Paper basis weight detection board/RX (PBWDB/RX) |

5 | Envelope detection board/TX (ENVDB/TX) | 6 | Envelope detection relay board (ENVDRB) |

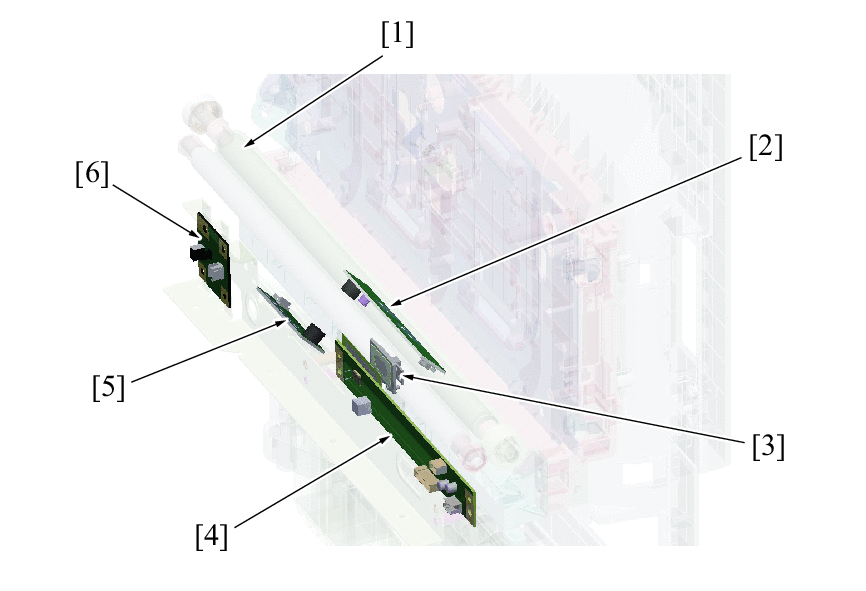

Basis weight detection mechanism

- There is a source of light on the paper basis weight detection board/TX, and white light is irradiated to the paper.

- The white light is penetrated the paper by part, and reaches the photodiode installed on the paper basis weight detection board/RX.

- There is a source of RGB light on the paper basis weight detection board/RX, and RGB light is irradiated to the paper.

- The RGB light reflects the paper, and reaches the photodiode installed on the paper basis weight detection board/RX.

- The basic weight of the feeding paper is decided according to the value of white light and RGB light that the photodiode detected.

1 | Source of RGB light | 2 | Reflected RGB light |

3 | Source of white light | 4 | Penetrated white light |

5 | Feeding paper | 6 | Photodiode |

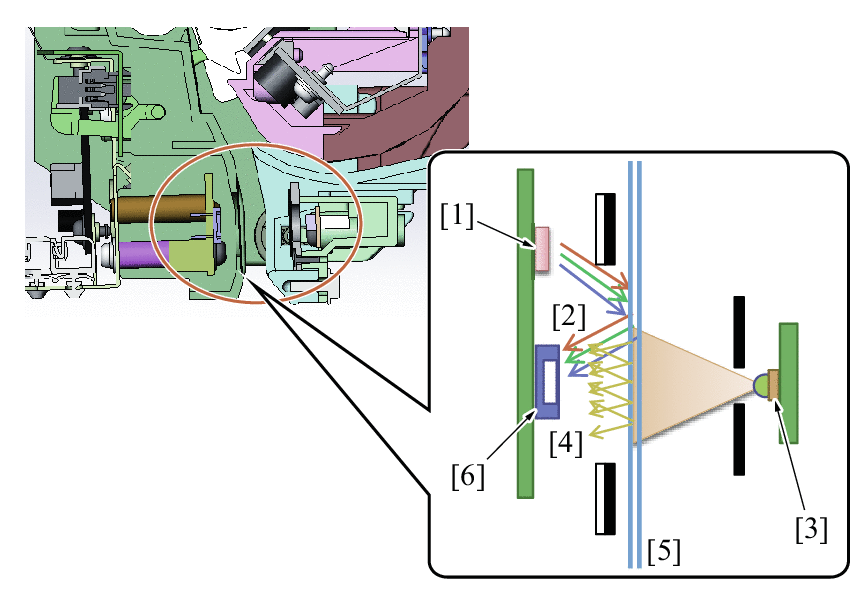

Envelope detection mechanism

- Papers come into contact with ultrasonic waves that are transmitted from the envelope detection board/TX. The ultrasonic waves are received on the envelope detection board/RX.

- The ultrasonic waves attenuate due to the air layer between papers when the paper kind is envelope.

- The voltage at the receiver is checked. A determination of envelope is made if the voltage is the same as or less than a predetermined value.

1 | Envelope detection board/RX (ENVDB/RX) | 2 | Ultrasonic waves |

3 | Feeding paper | 4 | Envelope detection board/TX (ENVDB/TX) |